Track record 02 Power Brush for Cleaner

Case summary

outline

We have been working from early on to reduce the weight and increase the torque of motors in order to meet the needs of customers. Since the power brush rotates the brush at high speed in a small nozzle, the motor that drives the brush is required to have very strict performance.We provide the optimum motor for power brushes by optimizing the winding of the motor, optimizing the number of poles, and adopting high-performance magnets. By these measures, it is possible to suppress the load on the power brush and the temperature rise, and to reduce the size at the same time.

In the future, it is expected that the motors used in power brushes will be required to be smaller and have higher torque. We will respond quickly to these trends and provide the optimum motors to customers.

Problem

- Achieving weight reduction / miniaturization and high torque at the same time

- Suppressing the load on the power brush and temperature rise

Measures

- Optimize motor windings and number of poles

- Adopt high-performance

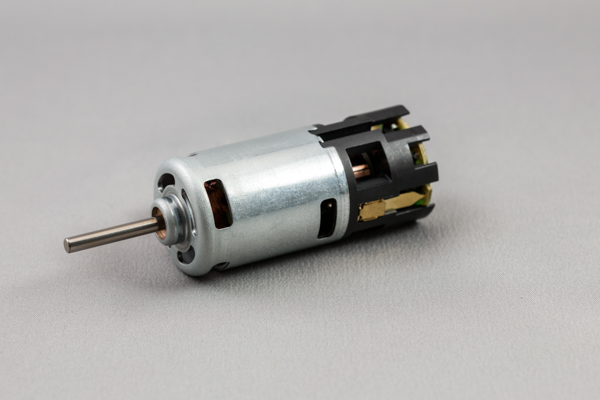

Finished product

An example of a motor used for power brush.

The photo is for illustrative purposes only.