About "Motor Performance Chart"

What is “Motor Performance Chart”?

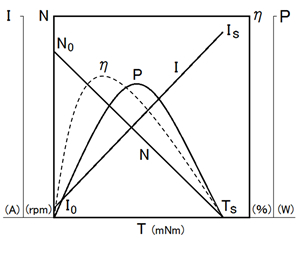

This performance chart is written in the torque reference system. |

|

|

Based on torque T [Nm], Rotation speed : N [r / min] Current : I [A] Output : P [W] Efficiency : η [%] |

|

| Torque is the moment of force around the axis of rotation and represents the rotational force of the motor. The unit is [Nm]. |

|

How to read “Motor Performance Chart”

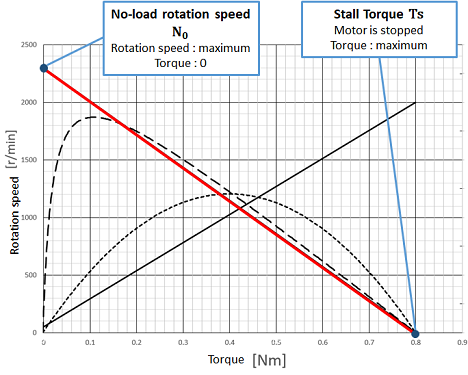

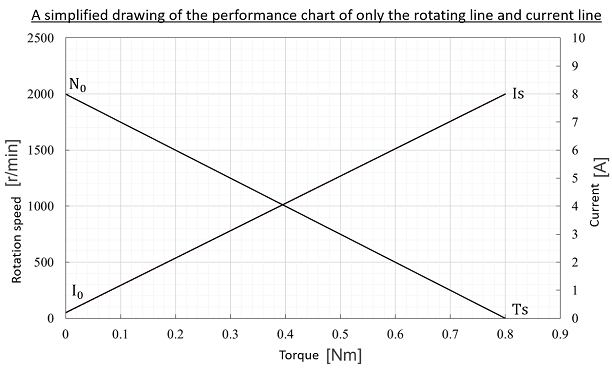

Torque - Rotation |

|

|

Horizontal axis : Torque [Nm] Vertical axis : Rotation speed [r / min] |

|

|

No-load rotation speed N0 [r/min] Rotation speed when the motor is not loaded |

|

|

Stall torque Ts [Nm] Torque when the load of the motor is increased and the rotation of the motor is stopped |

|

|

Examples from the right figure N0=2300 [r/min] Ts = 0.8 [Nm] |

|

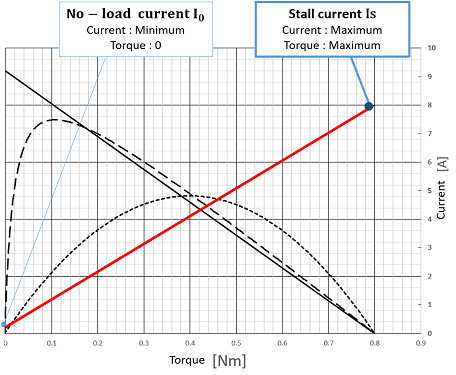

Torque - Current |

|

|

Horizontal axis : Torque [Nm] Vertical axis : Current [A] |

|

|

No-load current I0 [A] Current that flows when a voltage is applied when the motor is not loaded |

|

|

Stall current Is [A] Current when the load of the motor is increased and the rotation of the motor is stopped |

|

|

Examples from the right figure I0 = 0.2 [A] Is = 8.0 [A] |

|

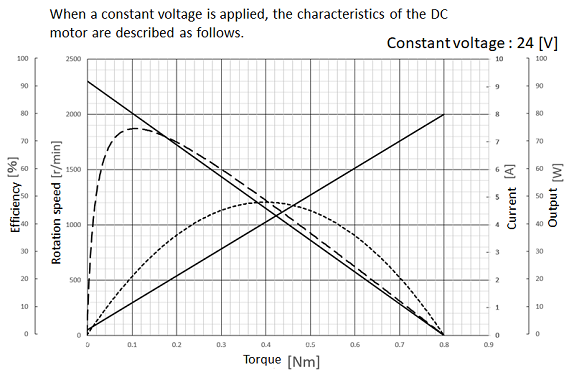

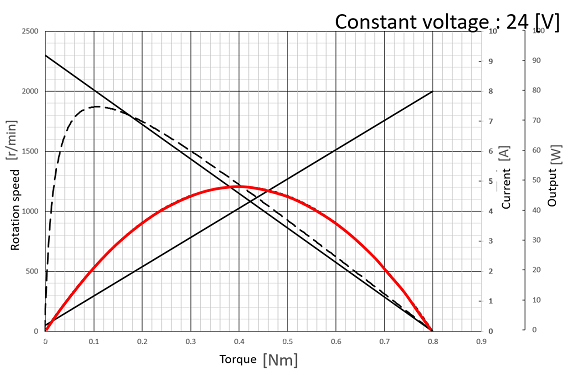

Torque – Output |

|

|

Horizontal axis : Torque [Nm] Vertical axis : Output [W] |

|

| Output P [W] = N [rad/sec] × T [Nm] = N [r/min] × 2π/60 × T [Nm] The output line can be drawn from the rotation line. |

|

|

Example: Output at 0.1 [Nm] 2000[r/min] × 2π/60 × 0.1[Nm] = 21[W] |

|

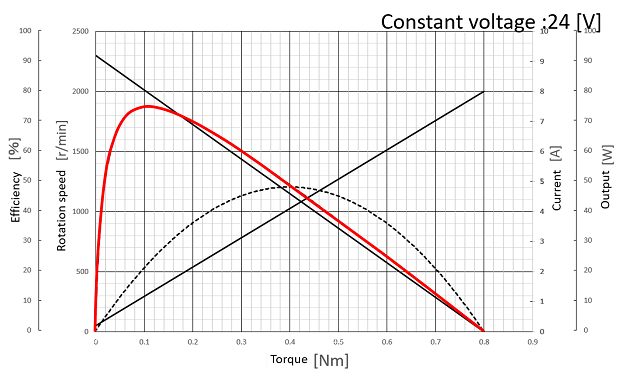

The efficiency line |

|

|

Horizontal axis : Torque [Nm] Vertical axis : Efficiency [%] |

|

| Efficiency η [%] = (P [W])/((V × I) [W]) × 100 The efficiency line can be drawn from the current line and applied voltage. |

|

|

Example : Efficiency at 0.1 [Nm] 21/(24×1.2) ×100 = 73[%] |

|

Changes in each parameter

Changing the following four parameters will affect the performance chart. |

|

|

・Voltage of power-supply Change in voltage applied to the motor |

|

|

・Number of turns Change in the number of turns of the winding wound around the core |

|

|

・Diameter of winding wire Change in wire diameter of the winding wound around the core |

|

|

・Type of magnet Change in magnetic force |

|

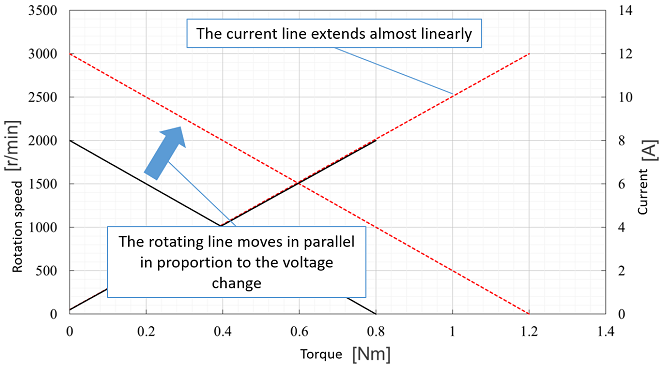

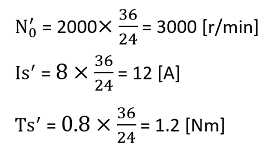

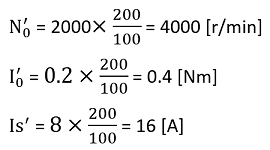

Voltage of power-supplyIf only the voltage of power-supply changes, the performance is proportional to the change of the voltage of power-supply. |

|

| V :Original voltage V′:Voltage after changed |

|

| N0′ = N0×V′/V | |

| Is′ = Is×V′/V | |

| Ts′ = Ts×V′/V | |

|

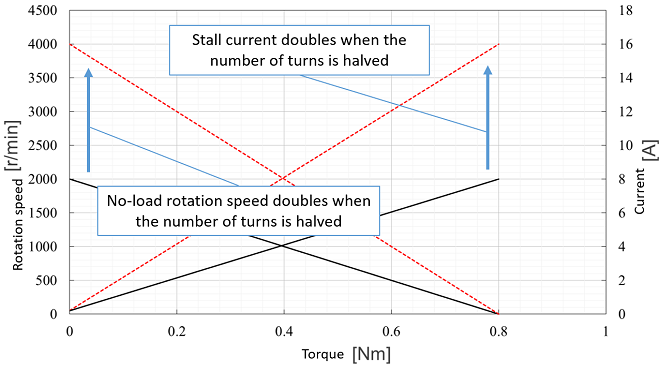

Number of turns

When the number of turns is reduced, the no-load rotation speed and stall current increase proportionally. |

|

|

n :original number of turns n′:number of turns after changed |

|

| N0′ = N0×n/n′ | |

| I0′= I0 × n/n′ | |

| Is′ = Is×n/n′ | |

| Ts′ = Ts | |

|

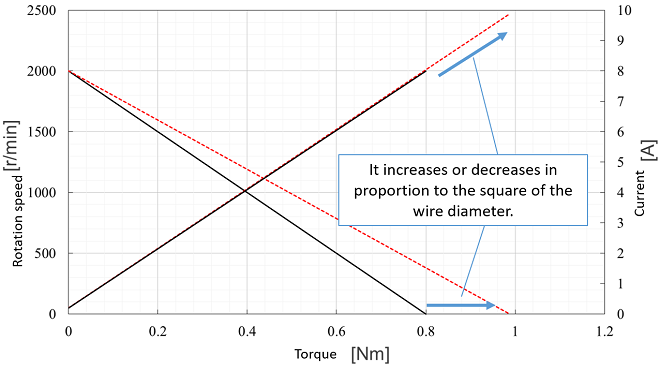

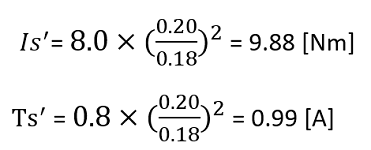

Diameter of winding wireWhen the diameter of winding wire is increased, the stall torque and stall current change in proportion to the square of the diameter of winding wire. |

|

|

Φ:original diameter of winding wire Φ′: diameter of winding wire after changed |

|

| N0′ = N0 | |

| Is′ = Is×( Φ′/Φ )2 | |

| Ts′ = Ts ×( Φ′/Φ )2 | |

|

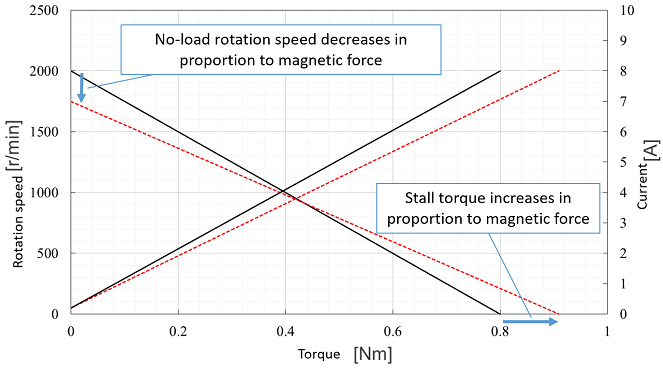

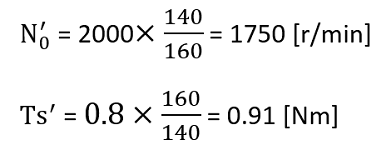

Type of magnetPerformance changes as the strength of the magnetic force changes. The dry type is weaker and the wet type is stronger. |

|

| N0′ = N0 × m/m′ |  |

| Is′ = Is | |

| Ts′ = Ts × m′/m | |

|